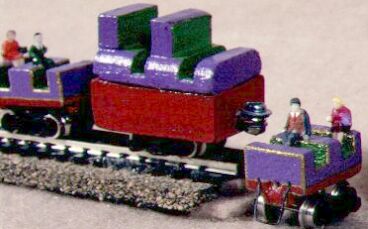

From The Ground Up The only way to build a coaster is from the ground up, testing and extending the track upward as each new section has proved itself to work right. I'd show you a track diagram, but it's very chaotic because the tracks cross and re-cross each other like a bowl of spaghetti so I don't think it would do anything for you—the diagram still confuses even me. So let the photos tell the story. Anyway, I added one piece of flextrack at a time, and I always built up piles of Corningware insulation foam board to hold all new track until testing it with a coaster car showed that the new piece worked okay and sent the car into the old track at the proper velocity. Once I accepted the performance, I built usually about seven track "trestles"—one every four inches for the 29.25" Atlas flextrack. They were made from white-painted 3/16" x 3/16" x 3' balsa for both the verticals and the horizontal framing members which I always put every 6". I always made the trestles 2.25" longer than the distance from the foam on the coaster table to the underside of the track, because the trestles were all inserted into holes in the 1.5"-thick Corningware insulation foam board that covered my coaster table (a 36" x 80" door I'd put legs on), and there was an extra ¾" at the top to hold the very important safety device called the railings. These were found to be essential because cars that fly off and hit things after derailments tend to be unhappy—and therefore uncooperative—cars. The foam as a base for the trestles was very effective as a trestle holder—no glue was needed. All I needed to do was insert the trestles into a couple of holes and they held the trestles snuggly. Making the holes turned out to be less of a snap than I first thought, however. Here's what didn't work: Drilling holes—the material is easy to drill but the holes aren't right: the material springs back and tends to fill the hole. A center punch—the shape is wrong. A 3/16" x 3/16" square rod—it cracked the material up as it made the hole. What did work was a sequence. Each of the three items that follow were pushed into the foam until I hit the table: a regular center punch (1/8" at the sharp end and ¼" at the handle), then a coarser punch (5/32"-wide at the flat punch end and ¼" at the handle), and then a 3/16" coarser punch. All those were round, but my forth and final hole creation tool was the 3/16" x 3/16" square iron rod, which you may recall didn't work alone (above). This latter was inserted with no twisting motion but with an eye to creating a somewhat squared hole so that the 3/16" balsa would have a properly shaped target hole. Note: I painted and sceniked the foam board before I started building on it because it was obvious I'd never be able to get into much of the trestle jungle and do it later—see photos. All the balsa pieces were pre-painted for similar reasons. The track was glued to the horizontal balsa track support joists with slow, thick CA. The glue I used for balsa to balsa applications was Aleene's Tacky glue, which seems to be stronger than Elmer's because it's a bit thicker. I had 130 clothespins at one time in use as I glued the innumerable 1/16" x 3/16" diagonals onto the trestles, and I also used the clothespins for holding the track to the trestles while the CA dried. The many hundreds of balsa pieces were painted the easy way: I bought a 4' piece of plastic rain gutter and fastened gutter ends to each end and poured a couple of inches of diluted (1:1 with water) flat white latex house paint into it. Then I dipped about 25 pieces at a time and moved them around a bit so paint would get between balsa strips. Finally I laid the wet balsa on a painter's disposable thin plastic drop cloth (it's like kitchen plastic wrap and it comes in 100' x 6' rolls and has tape already attached to one edge) with which I'd covered my garage floor. My tightest horizontal curve radius turned out to be 4". The tighter the curve, the more the coaster slows down as it traverses it. One 2" hill followed by two 1" hills was a configuration that I repeated half a dozen times on my coaster layout, since I knew it worked properly. Yes, I'd have liked more pronounced dips and hills, but I tried a few more and the speed of the car was ridiculous and the tendency to derail infamous. But I made up for this weakness with a scale height of 480 feet! This required that the coaster was hoisted up to an actual 36" hoist apex. Let's see Disneyland or Cedar Point try that one! |